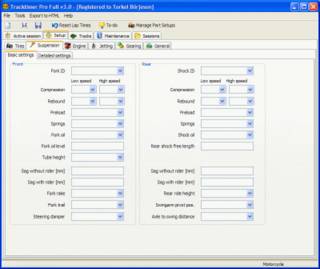

The suspension setup possibilities for motorcycles are now hugely improved thanks to input from Espen at

www.esp1tech.com. A place for everything, just as it should be.

I have also taken the plunge to create an "intelligent" stock function, a part status group (or more) can now be assigned as a "Stock group" and when it is two new columns are shown: Required Qty and Supplier. Together with the new supplierdatabase this means that you can easily create reports and buy orders to be either faxed or e-mailed directly to the supplier. All items where qty is less than required qty are also indicated in the program.

This is also the best place to enter all inspection intervals, task lists and such since an item in a stock group can have a qty count of zero without being removed. Think of the stock group as the complete part list from where you move parts to other groups.

Most of this has already been implemented, what remains is the supplier database and the reports.